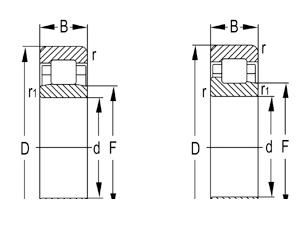

Cylindrical rollers have linear contact with the raceway, and the bearings can carry heavier radial load. Cylindrical bearing applications are found in situations characterized by heavy load and shock load and also high rotation speed. The N type and NU type bearings can be movable along the shaft. They can adapt to the position changes between the shaft and housing caused by the thermal expansion or the mounting error and are most suitable for free end shafts. NJ and NF types can accept certain axial load in one direction, and NH and NUP types can accept certain axial load in two directions. Inner ring and outer ring can be separable, so they are convenient to mount and dismount.

Applications

These bearings are mostly found in middle-sized and large-sized motors, electricity generators, internal combustion engines, gas turbines, machine tool spindles, deceleration devices, unloading and lifting machines and other industrial machines.

|

Bearing No. |

Boundary dimensions |

Basic load rating(kN) |

Limiting speeds |

Mass | ||||||

|

mm |

Dynamic |

Static |

rpm |

Kg | ||||||

|

d |

D |

B |

rs min |

rs1 min |

Cr |

Cor |

Grease |

Oil |

| |

|

NU304E |

20 |

52 |

15 |

1.1 |

0.6 |

31.5 |

26.9 |

13,000 |

15,000 |

0.176 |

|

NU305E |

25 |

62 |

17 |

1.1 |

1.1 |

41.5 |

37.5 |

11,000 |

13,000 |

0.275 |

|

NU306E |

30 |

72 |

19 |

1.1 |

1.1 |

53 |

50 |

9,300 |

11,000 |

0.398 |

|

NU307E |

35 |

80 |

21 |

1.5 |

1.1 |

71 |

71 |

8,100 |

9,600 |

0.545 |

|

NU308 |

40 |

90 |

23 |

1.5 |

1.5 |

58.5 |

57 |

8,000 |

9,400 |

0.658 |

|

NU308E |

40 |

90 |

23 |

1.5 |

1.5 |

83 |

81.5 |

7,200 |

8,500 |

0.754 |

|

NU309 |

45 |

100 |

25 |

1.5 |

1.5 |

74 |

71 |

7,200 |

8,400 |

0.877 |

|

NU309E |

45 |

100 |

25 |

1.5 |

1.5 |

97.5 |

98.5 |

6,500 |

7,600 |

0.996 |

|

NU310 |

50 |

110 |

27 |

2 |

2 |

87 |

86 |

6,500 |

7,700 |

1.14 |

|

NU310E |

50 |

110 |

27 |

2 |

2 |

110 |

113 |

5,900 |

6,900 |

1.3 |

|

NU311 |

55 |

120 |

29 |

2 |

2 |

111 |

111 |

5,900 |

7,000 |

1.45 |

|

NU311E |

55 |

120 |

29 |

2 |

2 |

137 |

143 |

5,300 |

6,300 |

1.65 |

|

NU312 |

60 |

130 |

31 |

2.1 |

2.1 |

124 |

126 |

5,500 |

6,500 |

1.8 |

|

NU312E |

60 |

130 |

31 |

2.1 |

2.1 |

150 |

157 |

4,900 |

5,800 |

2.05 |

|

NU313 |

65 |

140 |

33 |

2.1 |

2.1 |

135 |

139 |

5,100 |

6,000 |

2.23 |

|

NU313E |

65 |

140 |

33 |

2.1 |

2.1 |

181 |

191 |

4,600 |

5,400 |

2.54 |

|

NU314 |

70 |

150 |

35 |

2.1 |

2.1 |

158 |

168 |

4,700 |

5,500 |

2.71 |

|

NU314E |

70 |

150 |

35 |

2.1 |

2.1 |

205 |

222 |

4,200 |

5,000 |

3.1 |

|

NU315 |

75 |

160 |

37 |

2.1 |

2.1 |

190 |

205 |

4,400 |

5,200 |

3.28 |

|

NU315E |

75 |

160 |

37 |

2.1 |

2.1 |

240 |

263 |

4,000 |

4,700 |

3.74 |

|

NU316 |

80 |

170 |

39 |

2.1 |

2.1 |

190 |

207 |

4,100 |

4,800 |

3.86 |

|

NU316E |

80 |

170 |

39 |

2.1 |

2.1 |

256 |

282 |

3,700 |

4,400 |

4.22 |

|

NU317 |

85 |

180 |

41 |

3 |

3 |

212 |

228 |

3,900 |

4,600 |

4.54 |

|

NU317E |

85 |

180 |

41 |

3 |

3 |

291 |

330 |

3,500 |

4,100 |

4.81 |

|

NU318 |

90 |

190 |

43 |

3 |

3 |

240 |

265 |

3,700 |

4,300 |

5.3 |

|

NU318E |

90 |

190 |

43 |

3 |

3 |

315 |

355 |

3,300 |

3,900 |

5.72 |

|

NU319 |

95 |

200 |

45 |

3 |

3 |

259 |

285 |

3,400 |

4,000 |

6.13 |

|

NU319E |

95 |

200 |

45 |

3 |

3 |

335 |

385 |

3,100 |

3,600 |

6.62 |

|

NU320 |

100 |

215 |

47 |

3 |

3 |

299 |

335 |

3,300 |

3,800 |

7.49 |

|

NU320E |

100 |

215 |

47 |

3 |

3 |

380 |

425 |

2,900 |

3,500 |

8.57 |

|

NU321 |

105 |

225 |

49 |

3 |

3 |

320 |

360 |

3,100 |

3,700 |

8.53 |

|

NU322 |

110 |

240 |

50 |

3 |

3 |

360 |

400 |

3,000 |

3,500 |

10 |

|

NU322E |

110 |

240 |

50 |

3 |

3 |

450 |

525 |

2,700 |

3,100 |

11.1 |

|

NU324 |

120 |

260 |

55 |

3 |

3 |

450 |

510 |

2,700 |

3,200 |

12.8 |

|

NU324E |

120 |

260 |

55 |

3 |

3 |

530 |

610 |

2,400 |

2,800 |

13.9 |

|

NU326 |

130 |

280 |

58 |

4 |

4 |

560 |

665 |

2,500 |

2,900 |

17.4 |

|

NU326E |

130 |

280 |

58 |

4 |

4 |

615 |

735 |

2,200 |

2,600 |

19.4 |

|

NU328 |

140 |

300 |

62 |

4 |

4 |

615 |

745 |

2,300 |

2,700 |

21.2 |

|

NU328E |

140 |

300 |

62 |

4 |

4 |

665 |

795 |

2,100 |

2,400 |

23.2 |

|

NU330 |

150 |

320 |

65 |

4 |

4 |

665 |

805 |

2,100 |

2,500 |

25.3 |

|

NU330E |

150 |

320 |

65 |

4 |

4 |

760 |

920 |

1,900 |

2,300 |

28.4 |